In high-stakes projects—whether in government infrastructure, defense systems, or national data platforms—quality issues are more than temporary setbacks. If they recur, they erode trust, inflate costs, and threaten mission readiness.

The most effective way to break this cycle is Root Cause Analysis (RCA)—a disciplined method for identifying the true source of a problem, not just its symptoms.

Why RCA Matters in Complex Projects

A recurring quality issue signals that the corrective actions taken were insufficient. In my experience, this happens when teams focus on patching defects quickly rather than eliminating their source.

RCA shifts the conversation from “How do we fix this?” to “Why did this happen in the first place—and how do we ensure it never happens again?”

Key Principles of Effective RCA

- Separate Symptoms from Causes

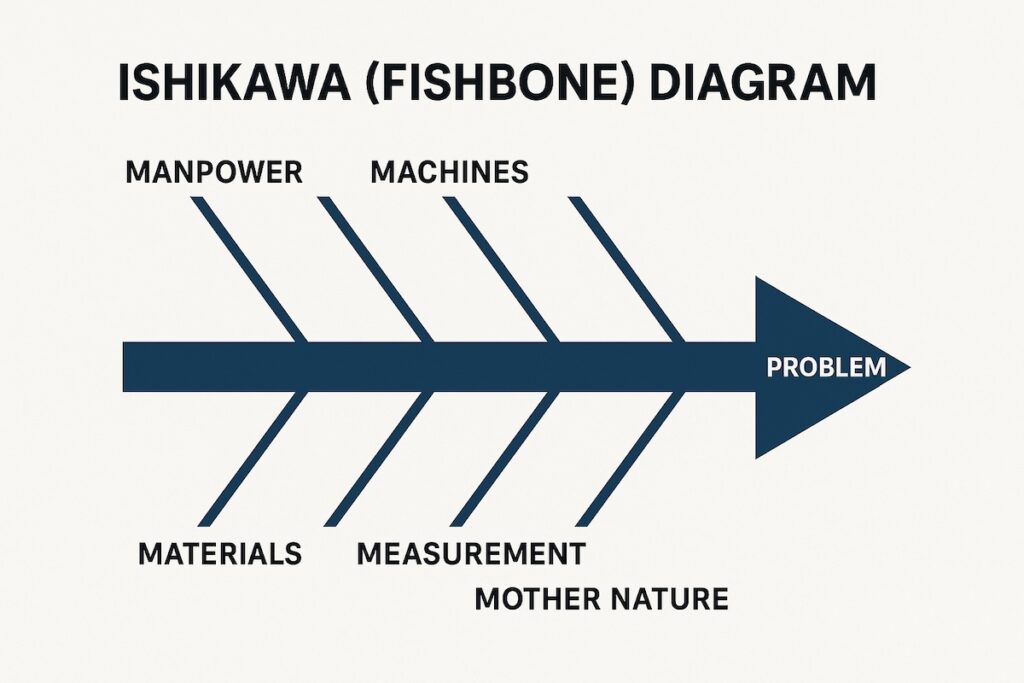

A defect in output is the visible symptom; the underlying cause could be a flawed process, insufficient training, or a missing control. - Use a Structured Approach

Tools like the 5 Whys, Fishbone Diagram (Ishikawa), or Failure Mode and Effects Analysis (FMEA) bring discipline and repeatability to the investigation. - Focus on Systemic Factors

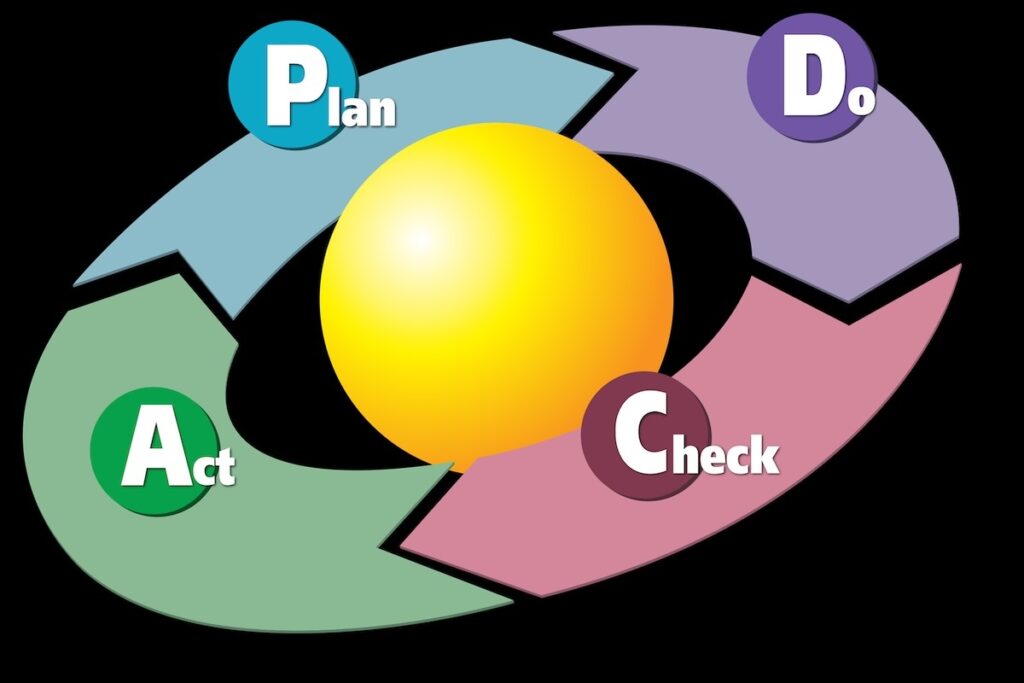

In public-sector programs, quality failures often stem from systemic gaps—procurement policies, governance processes, or supplier management—not from isolated mistakes. - Implement Permanent Corrective Actions

Corrective measures should address the process, not just the product. That might mean revising standard operating procedures, retraining teams, or redesigning workflows.

Real-World Example 1: Secure Data Exchange Platform

In a multi-agency data exchange project, repeated data validation errors were slowing down onboarding. An initial fix—adding manual reviews—reduced immediate errors but added delays.

RCA revealed that the mapping templates used by multiple agencies were outdated and inconsistent. The permanent solution was a centralized, version-controlled mapping library. Errors dropped by 90%, and onboarding speed increased.

Real-World Example 2: Critical Infrastructure Component Failures

A defense facility experienced repeated failures in a cooling system. Replacing the components solved the short-term problem—but failures continued.

RCA traced the root cause to environmental factors: airborne particulates clogging air intakes. The long-term fix involved adding filtration systems and updating maintenance schedules. Failures ceased entirely.

Integrating RCA into Project Quality Management

- Include RCA in the Quality Management Plan – Make it a standard process for significant defects or non-conformities.

- Link RCA Outcomes to Risk Registers – Recurring issues often signal underestimated risks.

- Track and Share Lessons Learned – Store RCA findings in an accessible knowledge base to prevent similar issues in future projects.

- Assign Accountability – Ensure that corrective actions identified through RCA are tracked to completion.

The Strategic Payoff

In mission-critical environments, RCA delivers three key benefits:

- Prevents Repeat Failures – Protecting timelines, budgets, and reputations.

- Improves System Resilience – Strengthening processes against future risks.

- Builds Organizational Learning – Turning each issue into a long-term capability gain.

Closing Perspective

Quick fixes may satisfy immediate pressures, but only Root Cause Analysis stops problems from returning. In high-impact projects, it’s the difference between firefighting and true quality leadership.

When RCA is embedded into project culture, recurring issues become rare—and stakeholders gain confidence that your team doesn’t just solve problems, it solves them permanently.