When quality slips, projects pay the price—missed deadlines, ballooning costs, and, worst of all, damaged stakeholder trust. The PMBoK’s Project Quality Management knowledge area gives us the framework to avoid these pitfalls, but translating guidelines into a real, working Quality Management Plan (QMP) is where the magic happens.

In my experience leading cross-functional and fully remote teams, an effective QMP is not just a compliance document—it’s a playbook for delivering outcomes that satisfy both the specification and the customer’s expectations.

Understanding the Purpose of the QMP

A Quality Management Plan documents how your project will define, manage, and verify quality. It covers three key processes from PMBoK:

- Plan Quality Management – Define quality requirements and how you’ll meet them.

- Manage Quality – Execute quality assurance activities to ensure processes deliver the desired results.

- Control Quality – Monitor specific results to verify they meet the agreed standards.

The QMP is the connective tissue between what’s promised and what’s delivered.

Start with the End in Mind

Before you draft a single section, anchor your QMP in two realities:

- The Voice of the Customer (VoC) – What does “quality” mean to them? Reliability? Precision? Speed?

- The Definition of Done – What measurable evidence will confirm the deliverable meets quality expectations?

Clarity here ensures every quality activity has purpose and relevance.

Key Components of an Effective QMP

1. Quality Objectives

Translate stakeholder needs into clear, measurable targets. For example:

- “Reduce defect rate in final deliverables to <1%.”

- “Achieve user satisfaction score of 4.5/5 or higher in UAT.”

2. Quality Standards

Identify which standards apply—these may be industry-specific (ISO 9001, IEEE), regulatory, or internal benchmarks.

3. Quality Metrics and KPIs

Select quantifiable indicators. Examples include defect density, first-pass yield, response time, and customer satisfaction scores.

4. Roles and Responsibilities

Define who owns each quality activity—from QA engineers to product owners—and how escalation works when non-conformance occurs.

5. Quality Assurance Activities

List proactive measures to prevent defects—process audits, peer reviews, continuous integration checks.

6. Quality Control Activities

Define inspection, testing, and verification steps. Specify sampling sizes, acceptance criteria, and defect categorization.

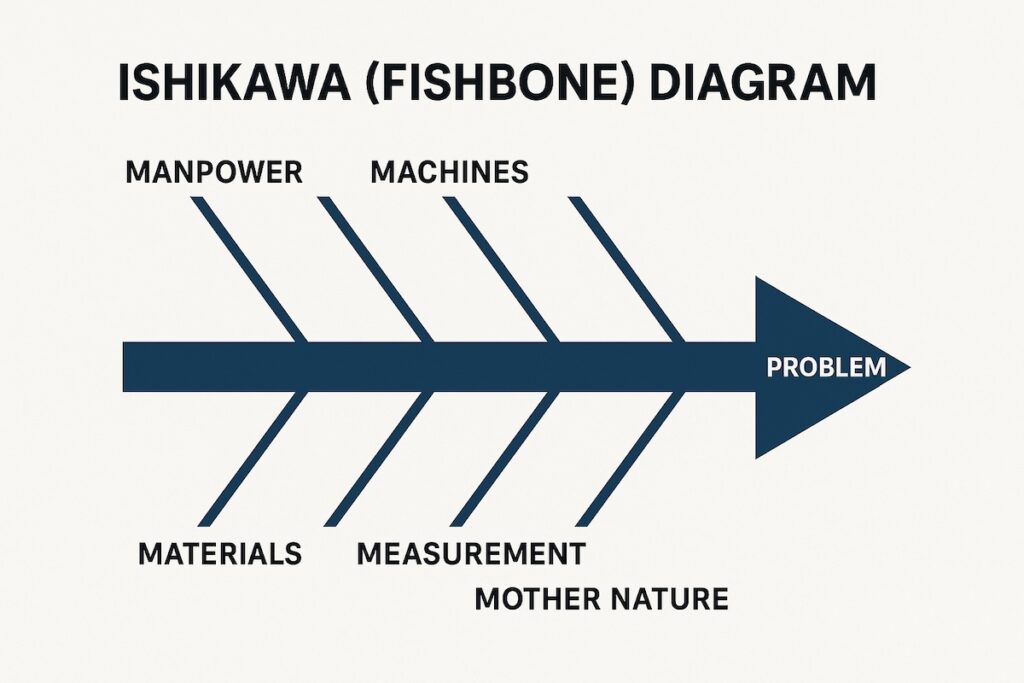

7. Tools and Techniques

Reference methods like Cause-and-Effect Diagrams, Control Charts, or Six Sigma DMAIC where applicable.

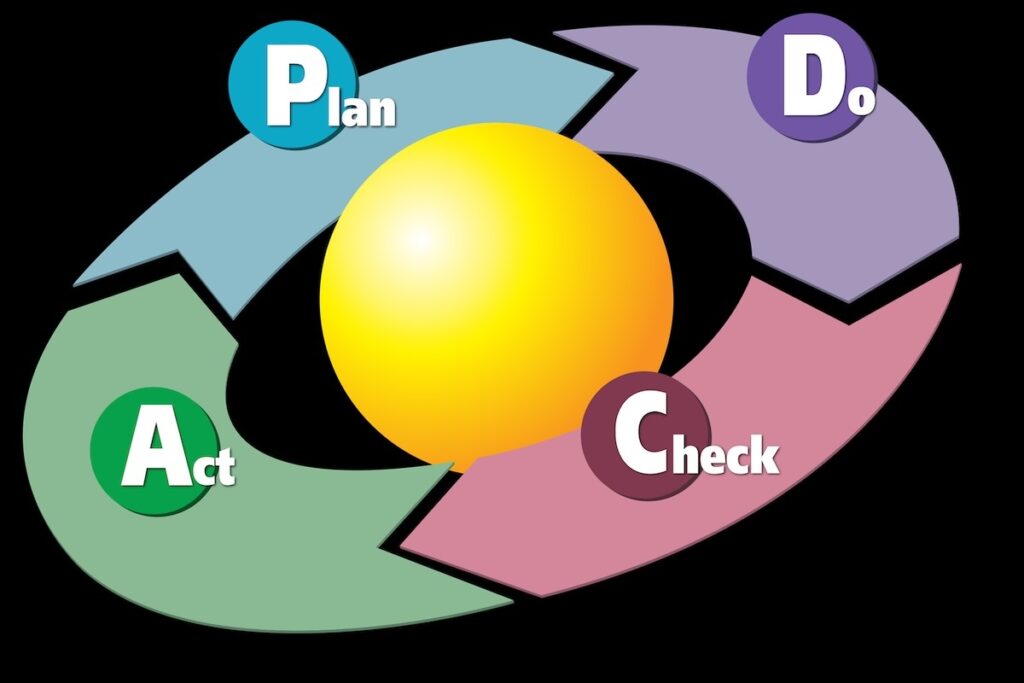

8. Continuous Improvement Strategy

Plan for feedback loops that use lessons learned and performance data to adjust processes during the project, not after it’s over.

Linking Quality to Risk and Cost

A solid QMP also addresses the cost of quality (CoQ)—both the cost of doing things right (prevention and appraisal) and the cost of doing them wrong (internal and external failures). Pair this with your risk register to show how quality measures mitigate project risks.

Common Pitfalls to Avoid

- Overcomplication – A QMP that’s too rigid or filled with jargon will gather dust.

- Ignoring Early Buy-In – Stakeholders and team members must understand and commit to quality targets.

- Reactive Approach – Waiting for defects to appear instead of preventing them is the fastest route to failure.

From Paper to Performance

A QMP only delivers value if it’s integrated into daily project life. This means:

- Referencing it in sprint planning or status meetings.

- Tracking metrics in real time using dashboards.

- Updating it when changes occur in scope, technology, or regulations.

Final Thoughts

An effective Project Quality Management Plan is part blueprint, part mindset shift. It aligns the project team around what “good” looks like, embeds prevention into the process, and creates transparency for stakeholders.

As PMs, our challenge is to bridge the gap between planning and execution. When the QMP moves off the shelf and into active use, you transform it from a static document into a living driver of performance.