In complex projects, success isn’t just about staying on time and on budget—it’s about delivering an outcome that works, lasts, and meets the needs of those it serves. That requires more than just quality management or risk management in isolation.

In reality, the two disciplines are deeply connected. When managed together, they create a stronger framework for preventing problems, seizing opportunities, and building stakeholder confidence.

The Shared Goal: Project Resilience

Quality management focuses on ensuring deliverables meet agreed standards and requirements. Risk management focuses on identifying and responding to uncertainties that could affect project objectives.

The overlap? Both are about preventing negative outcomes and maximizing the chance of success. A defect in a product is both a quality issue and a realized risk.

Why Integration Matters

When quality and risk management operate in silos, gaps appear. Quality teams may focus narrowly on specifications without anticipating how external risks could impact them. Risk teams may focus on threats without considering how process and product quality can reduce their likelihood.

Integrating the two disciplines means:

- Risks related to quality are identified early.

- Quality assurance measures are designed with potential risks in mind.

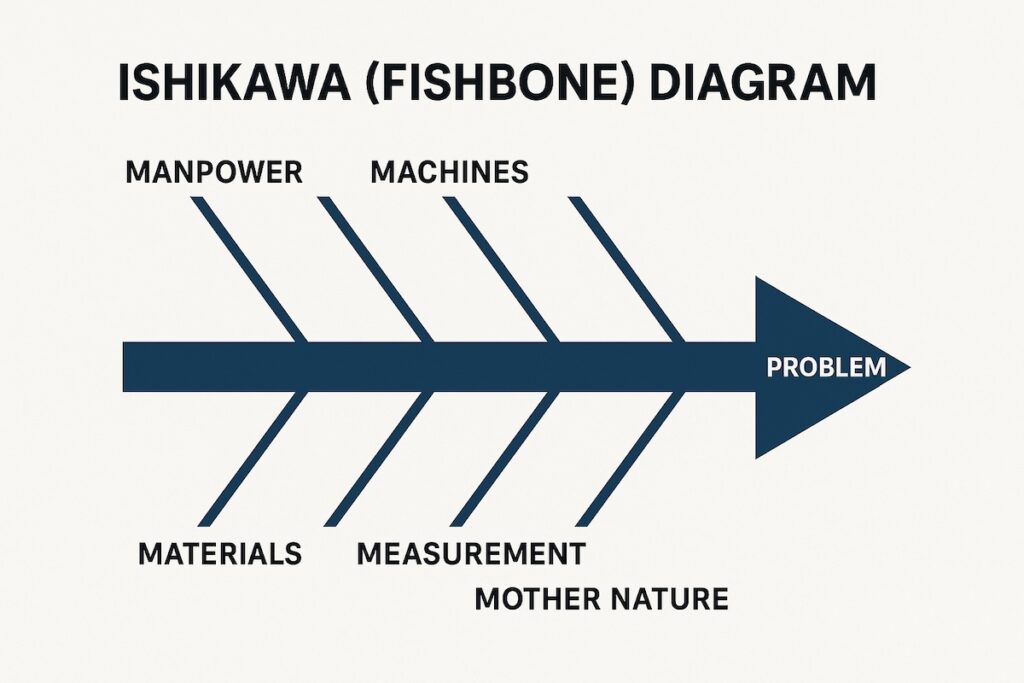

- Mitigation actions address both quality defects and their root causes.

Practical Ways to Align the Two

1. Include Quality Risks in the Risk Register

Don’t limit your register to schedule, budget, and resource risks. Capture quality-related risks—such as supplier performance, testing bottlenecks, or regulatory non-compliance—alongside other project threats.

2. Link Quality Metrics to Risk Triggers

Certain quality indicators can serve as early warning signs for risks. For example:

- A rise in defect density might indicate a risk to meeting delivery deadlines.

- A drop in first-pass yield could signal process breakdowns.

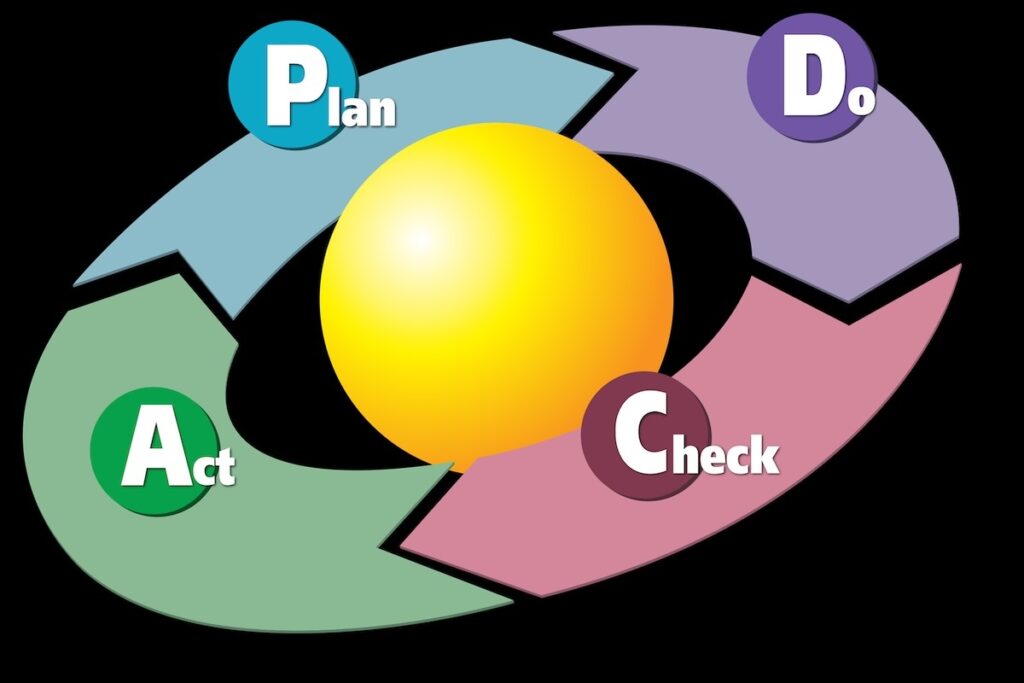

3. Coordinate Assurance and Mitigation Activities

Align quality assurance reviews with key risk reviews. This ensures both functions are looking at the same data and can act on it together.

4. Share Lessons Learned Across Functions

When a risk materializes and affects quality, document not only the fix but also the preventive action for future projects.

Example: Software Implementation in a Regulated Industry

In one enterprise resource planning (ERP) implementation for a healthcare provider, the quality team flagged recurring data integrity issues during testing. The risk management team recognized this as a potential compliance risk with serious legal implications.

By working together, they implemented an automated validation process. This reduced defects, mitigated the compliance risk, and accelerated user acceptance testing—demonstrating how an integrated approach delivers benefits on multiple fronts.

Building an Integrated Culture

Integration is more than process—it’s about culture. Project managers can encourage collaboration by:

- Holding joint risk–quality workshops during planning.

- Ensuring quality managers have visibility into the risk register.

- Including risk managers in quality assurance reviews.

When teams see quality and risk as complementary rather than separate, projects benefit from more robust decision-making and fewer last-minute surprises.

Final Word

In complex projects, quality management and risk management are two sides of the same coin. Integrated well, they protect the project from both known and unknown threats while improving outcomes. For PMs, this means fewer defects, fewer delays, and a stronger reputation for delivering projects that work as promised—long after handover.