One thing I’ve learned from decades in Silicon Valley IT projects is that quality isn’t a milestone—it’s a habit. You don’t “achieve” quality once and check it off the list. It’s the result of ongoing, intentional work to refine processes, adapt to change, and learn from experience.

That’s why continuous improvement is not just a nice-to-have—it’s a core pillar of effective Project Quality Management.

Why Continuous Improvement Belongs in Every Project

Project environments—especially in tech—are dynamic. Requirements shift, tools evolve, and new risks emerge halfway through execution. If your quality management plan is static, it will slowly drift out of alignment with reality.

Continuous improvement ensures that your quality processes evolve alongside your project. It creates a feedback loop where lessons are applied immediately, not saved for a post-mortem nobody reads.

Building Continuous Improvement into Quality Management

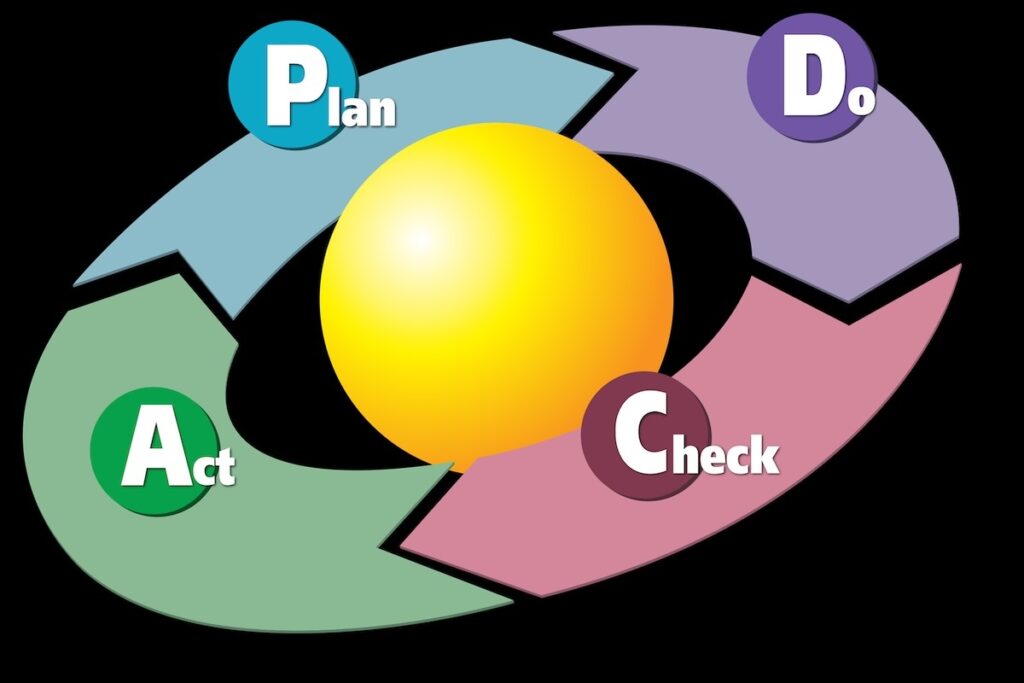

1. Use the PDCA Cycle as a Backbone

Plan–Do–Check–Act (PDCA) is the simplest, most reliable structure for embedding improvement:

- Plan: Define the process or quality measure you want to improve.

- Do: Implement changes on a small scale first.

- Check: Measure results against expectations.

- Act: Standardize improvements or refine further.

In one infrastructure migration project, my team used PDCA to streamline deployment scripts. By the second iteration, our release time dropped by 40%—and stayed there.

2. Make Quality Metrics Visible

If quality performance is buried in reports, the team loses the incentive to improve.

In a SaaS rollout I managed, we displayed live defect density and average resolution time on a shared dashboard. Seeing metrics in real time pushed the team to fix issues faster and rethink how defects were introduced in the first place.

3. Encourage Controlled Experimentation

Improvement often requires trying something new—and not every change will work. Create space for controlled experiments that are low-risk but high-learning.

For example, in a customer support portal project, we piloted automated regression tests on just 10% of modules. Once we confirmed a significant drop in post-release defects, we expanded automation across the platform.

4. Build Feedback Loops into Your Plan

Formal quality reviews shouldn’t wait until the end of the project. Add short feedback cycles at regular intervals—whether through retrospectives in Agile teams or monthly process reviews in Waterfall projects.

In a cloud integration program, these mid-project reviews revealed a recurring data mapping issue early enough to redesign the transformation logic before it caused large-scale errors.

Cultural Drivers of Continuous Improvement

Embedding continuous improvement into Project Quality Management isn’t just about tools—it’s about culture:

- Psychological safety so team members feel comfortable raising issues.

- Accountability that’s about learning, not blame.

- Leadership modeling—when leaders actively participate in improvement efforts, teams follow suit.

Avoiding Common Pitfalls

- Improvement without measurement – Changes must be tied to clear metrics.

- Too many changes at once – Incremental improvements stick; chaotic shifts don’t.

- Treating CI as an “extra” – It must be part of the daily workflow, not a side project.

Final Word

Continuous improvement transforms Project Quality Management from a compliance exercise into a living system. It ensures that what you deliver is not only fit for purpose today, but more resilient, efficient, and reliable tomorrow.

As I often remind my teams: A process left alone will degrade over time. A process you improve will deliver value long after the project closes.