I’ve lost count of how many projects I’ve seen where quality control was treated as a final gate—something you “do” once deliverables are complete. That mindset is a recipe for rework, budget bleed, and unhappy stakeholders.

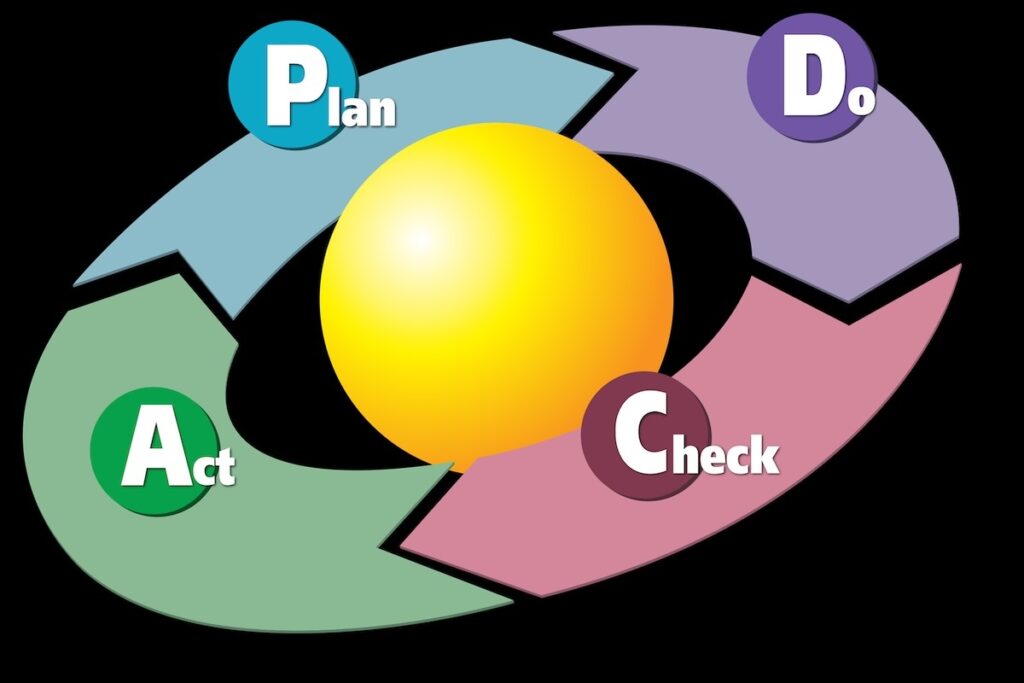

In the trenches, quality control works best when it’s continuous—and that’s where the PDCA cycle (Plan–Do–Check–Act) earns its keep. While PDCA is usually associated with process improvement, I’ve found it to be one of the most practical frameworks for keeping project deliverables on track.

Why PDCA Fits Project Quality Control

PDCA’s strength is its simplicity:

- Plan – Decide what quality looks like and how you’ll measure it.

- Do – Execute with the plan in mind.

- Check – Test results against expectations.

- Act – Fix what’s broken, and lock in what’s working.

The beauty here? It’s iterative. You don’t wait until the end to course-correct—you’re refining quality at every step.

Field Lesson 1: Planning Beyond the Checklist

Early in my PMO days, we managed a city infrastructure upgrade with multiple contractors. The “quality plan” was a generic checklist pulled from a previous project.

Halfway in, we realized it didn’t account for unique environmental standards for the region. Cue delays, extra inspections, and contractor overtime.

Lesson learned: The Plan phase must be tailored. Use historical data, yes—but validate it against the current project’s context, regulations, and risks.

Field Lesson 2: Doing with Discipline

On a large-scale ERP deployment, I watched a development team sprint ahead, confident they could “fix the details later.” The result? A mountain of rework when integration testing revealed mismatches with user workflows.

Lesson learned: The Do phase isn’t about speed—it’s about disciplined execution. Every build, every piece of code, every component should align with the defined quality measures.

Field Lesson 3: Checking Early and Often

I once worked on a defense system upgrade where testing was scheduled only after all modules were built. The “Check” phase became a bottleneck—errors cascaded, schedules slipped, and defect lists grew longer than the Gantt chart.

Lesson learned: Break quality checks into smaller, more frequent cycles. Catching a defect after 10% of the work is complete is far cheaper than finding it after 100%.

Field Lesson 4: Acting Decisively

In a public health data project, our “Check” revealed recurring data inconsistencies from one supplier. The initial instinct was to add more verification steps. But PDCA teaches you to Act on the root cause. We found the supplier’s validation scripts were outdated—fixing them solved the problem for the rest of the project.

Lesson learned: Don’t just patch the symptom—eliminate the source.

Making PDCA a Habit, Not an Event

Here’s how I embed PDCA into quality control in my PMOs:

- Map PDCA cycles to major milestones – but allow micro-cycles within sprints or work packages.

- Train teams on the “why” – people execute better when they understand the value of each step.

- Tie PDCA outcomes to metrics – defect density, rework hours, customer acceptance rates.

- Document improvements – every PDCA cycle adds to the organization’s quality knowledge base.

The Bottom Line from the Trenches

PDCA isn’t a silver bullet—it’s a discipline. In real project environments, it forces you to plan with intention, execute with precision, check without delay, and act without hesitation.

When you run PDCA in your quality control, you stop thinking of quality as something to “inspect in” at the end—and start building it in from the beginning.