Quality Assurance (QA) is one of those areas where theory and practice often part ways. On paper, QA is clean, procedural, and predictable. In the field, it’s messy—full of shortcuts, misunderstandings, and the occasional “we’ll fix it later” that never gets fixed.

Over my years running PMOs and watching projects stumble, I’ve seen the same mistakes repeat themselves like clockwork. If you can avoid these seven pitfalls, you’re already ahead of most organizations.

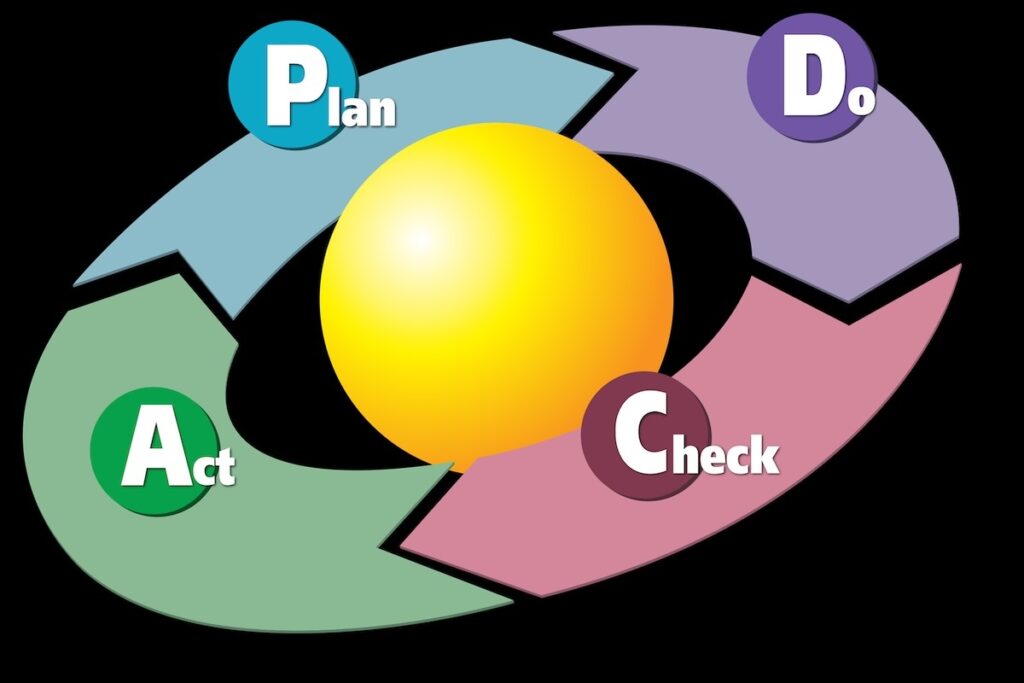

1. Treating QA as a Single Event

Too many teams think QA is something you “do” at the end, right before launch. By then, any major issue is expensive—or politically impossible—to fix.

Avoid it: Embed QA from day one. Make it part of planning, design, and every build cycle. Prevention is cheaper than correction, and early defects cost a fraction to fix.

2. Focusing Only on Functional Testing

If the product “works” but fails under load, frustrates users, or violates compliance, you haven’t met quality expectations. Functional checks alone won’t protect you.

Avoid it: Incorporate performance testing, usability testing, and compliance checks into the QA scope. Good QA looks at the whole picture, not just the happy path.

3. Overreliance on Automation

Automation is powerful, but it’s not a silver bullet. I’ve seen teams run the same automated scripts for months without realizing the test cases no longer reflect reality.

Avoid it: Pair automation with periodic manual exploratory testing. Automation checks the expected; humans find the unexpected.

4. No Clear Acceptance Criteria

Ambiguous acceptance criteria are the fastest route to “we thought it was done.” Without a shared definition of “done,” QA becomes subjective.

Avoid it: Define acceptance criteria in measurable terms before development starts. Everyone—developers, testers, and stakeholders—must agree on what pass/fail looks like.

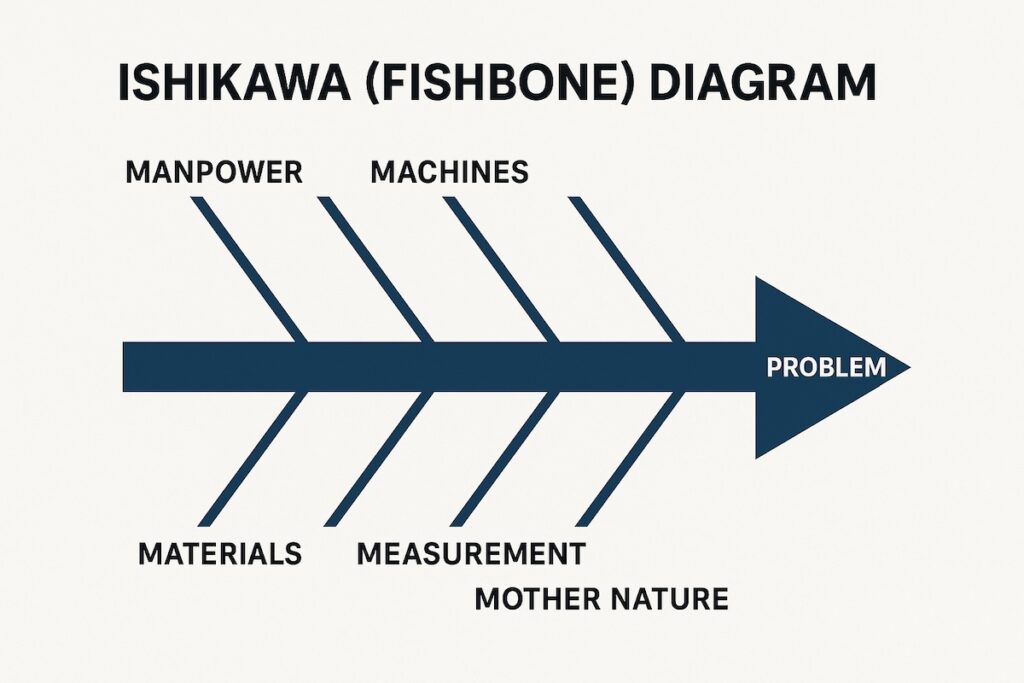

5. Ignoring Root Cause Analysis

Some teams fix defects without ever asking why they happened. The result? The same issues keep reappearing in slightly different forms.

Avoid it: For significant defects, run a root cause analysis. Address the process failure that allowed the defect in the first place—don’t just patch the symptom.

6. Rushing Under Deadline Pressure

I’ve been in the room when leadership says, “Cut testing by a week, we’ll handle issues post-launch.” Translation: we’ll spend twice as much fixing them in production.

Avoid it: Protect QA time as you would any critical path activity. If you must cut scope, remove lower-priority features—not QA.

7. QA Without Business Context

QA teams sometimes focus so narrowly on technical checks that they lose sight of business goals. You can pass every technical test and still fail the project if the product doesn’t solve the user’s problem.

Avoid it: Keep business outcomes in view. QA should verify not just that the solution works, but that it works for the right reasons.

The Bottom Line from the Trenches

In every failed QA process I’ve investigated, the cause wasn’t lack of skill—it was lack of alignment. QA works when it’s integrated, understood, and valued as part of the delivery strategy, not a box to tick at the end.

If you want fewer defects, lower rework costs, and happier stakeholders, treat QA as a continuous partner to delivery, not an afterthought.