Introduction: Managing Quality Without Standing Still

In high-stakes project environments—whether in supply chains, manufacturing, or enterprise services—quality is not a one-time goal. It’s a moving target that must be chased through continuous improvement.

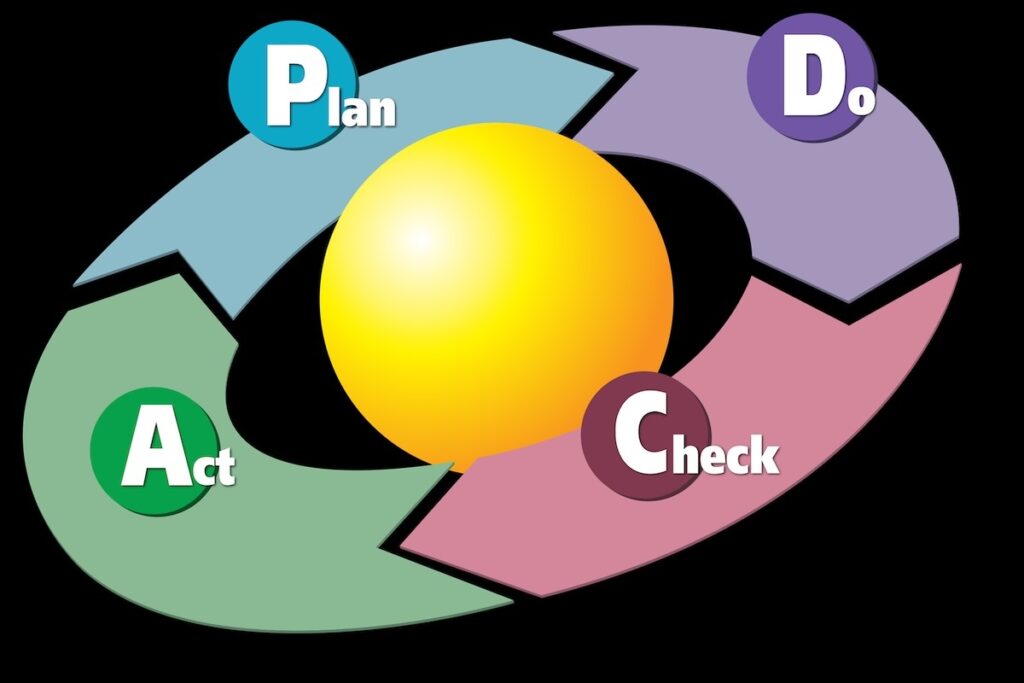

The Deming Cycle, also known as the PDCA Cycle (Plan–Do–Check–Act), is one of the most effective frameworks to help teams improve processes, reduce defects, and ensure customer satisfaction without halting production or overhauling systems.

This article walks you through the cycle, and how I’ve applied it in real-world logistics and manufacturing scenarios.

What Is the Deming Cycle?

The Deming Cycle is a four-step iterative model for continuous improvement:

1. Plan

Identify an opportunity and plan for change. Define the problem, collect relevant data, and outline measurable objectives.

2. Do

Implement the change on a small scale. Run pilot programs or limited-scope trials.

3. Check

Analyze the results and compare them against the expected outcomes. Look for deviations, defects, or new insights.

4. Act

If the change worked, implement it at scale. If it didn’t, revise the plan and test again. Then repeat the cycle.

Real-World Example #1: Warehouse Efficiency Optimization

Context:

At a fulfillment center in Ohio, we were facing increased order-picking time, especially during peak periods. Productivity was dipping, and error rates were climbing.

Application of PDCA:

Plan:

We suspected that picker pathing was inefficient. We mapped picker routes and identified high-frequency travel between distant shelves.

Do:

We launched a two-week pilot to rearrange 20% of high-demand SKUs closer to each other and retrained one picking team with the new layout.

Check:

We tracked picking time, order accuracy, and fatigue scores. Results showed a 22% reduction in average picking timeand fewer reported errors.

Act:

We expanded the new layout center-wide and developed a dashboard to continuously monitor SKU heatmaps—launching new PDCA cycles every quarter.

Real-World Example #2: Reducing Scrap in Plastic Packaging Line

Context:

In a packaging plant in Chennai, the extrusion line was producing excessive plastic scrap, increasing material costs and rework time.

PDCA in Action:

Plan:

Line managers hypothesized that temperature variation during startup caused material waste. We outlined a test plan with adjusted ramp-up procedures.

Do:

Trialed the new startup protocol during morning shifts for 10 days with full logging of machine data.

Check:

Scrap rates dropped by 18%, and quality control recorded higher consistency in material thickness.

Act:

Standard operating procedures were updated plant-wide. Further iterations of PDCA targeted the cool-down process and operator shift handovers.

How to Implement the Deming Cycle in Your Project

Step 1: Identify a Process Worth Improving

Look for recurring pain points—like:

- Customer complaints

- Rework rates

- Missed delivery deadlines

- Excess costs

- Bottlenecks in resource usage

Step 2: Follow the Four Steps of PDCA

Plan

- Define the problem and goal.

- Get input from people closest to the work.

- Collect baseline metrics.

Do

- Implement change in a controlled setting.

- Train a pilot group and observe closely.

Check

- Compare results with baseline.

- Use data (quantitative and qualitative).

- Interview frontline staff.

Act

- If it worked: document, train, and scale.

- If not: adjust and start again.

Step 3: Document Everything

Good records allow future PDCA cycles to be better informed. Use dashboards, internal wikis, and shared logs.

Step 4: Make It a Culture, Not a Tool

Embed PDCA in your team rituals:

- Use it in retrospectives.

- Add it to continuous improvement boards.

- Recognize employees who initiate PDCA efforts.

Best Practices from the Field

- Don’t rush “Plan”: Under-planned changes often lead to chaos. Take your time in diagnosis.

- Pilot, don’t plunge: Small experiments minimize risk while maximizing learning.

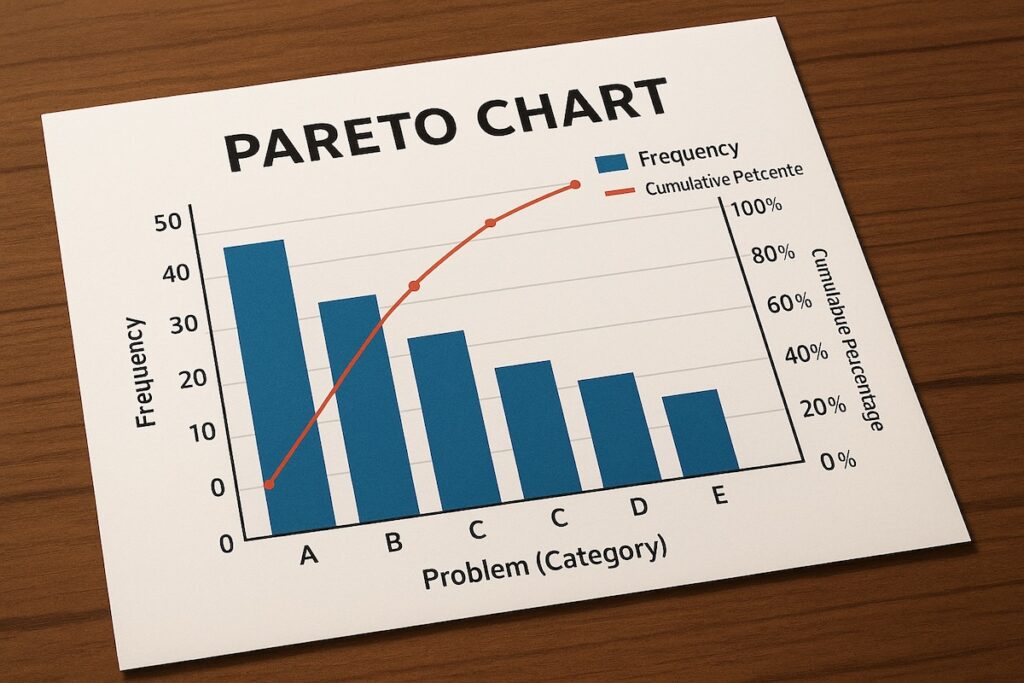

- Visualize progress: Use charts, A3 reports, and Kanban boards to track the cycle.

- Empower the frontline: Operators and coordinators often have the clearest view of what to fix.

Final Thoughts: Slow Iteration Beats Fast Fixes

In project operations, we’re often pressured to act fast. But quick fixes without structure often lead to inconsistent results—or worse, new problems.

The Deming Cycle offers disciplined change that’s small, strategic, and sustainable. It lets you adapt without disruption and improve without gambling.

For me, it has turned quality improvement from a reactive chore into a repeatable habit of progress. And in every logistics hub, factory, or digital transformation initiative I’ve worked on—that’s where real impact begins.